I want to be round.

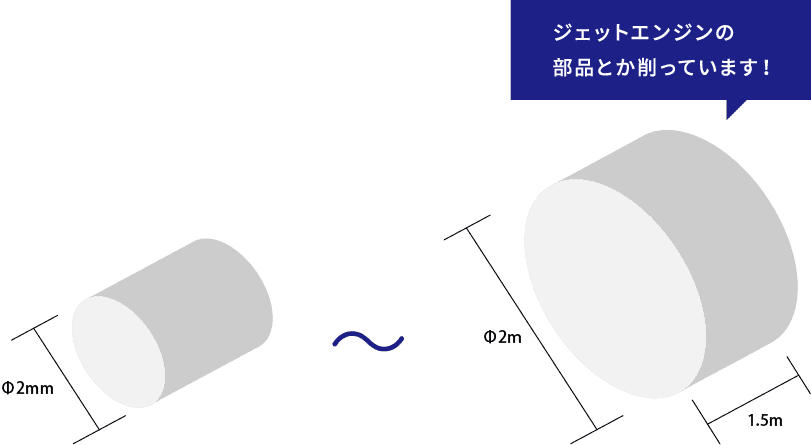

Shaving jet engine parts, etc.

Here are some of our strengths

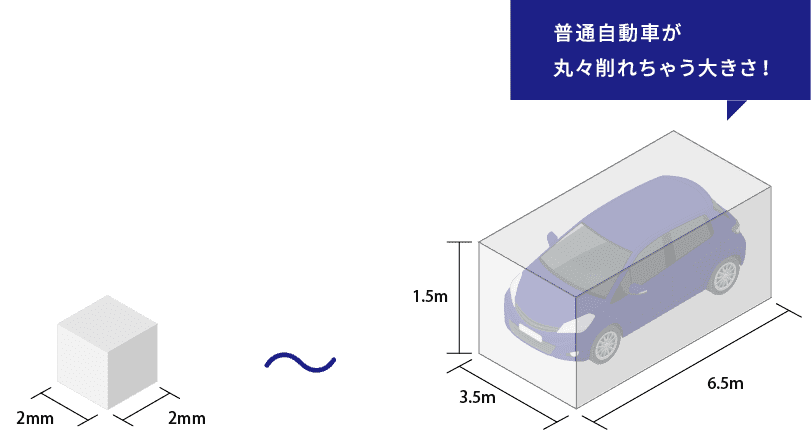

No need to worry about the size to be processed!!

Most work can be handled by our company.

Shaving jet engine parts, etc.

The size of a standard car can be cut down entirely

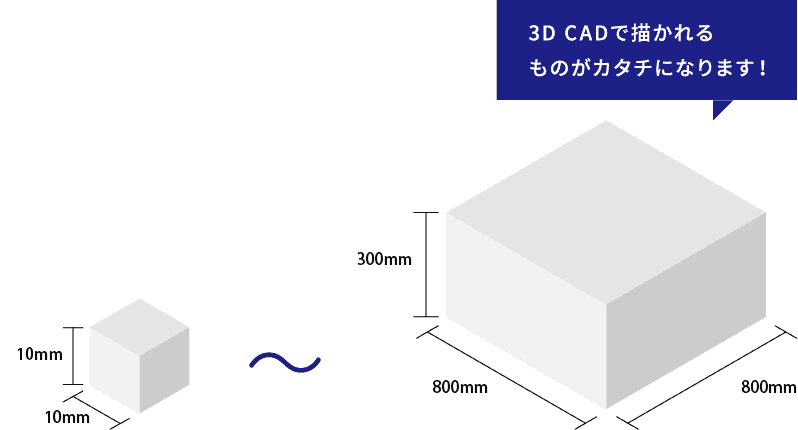

What you draw with 3D CAD takes shape.

The founder, Torimatsu Kikuchi, was a very skilled lathe operator in his hometown of Hitachi.

He lived through the postwar period with only one of his skills in an era when there were no NC machines.

We value originality and ingenuity, and have always continued to hone our skills.

And many of the technicians who have inherited our know-how over the past 60 years have grown up to support our company today.

Kikuchi Torimatsu has been processing a large number of pure copper and copper alloys since its establishment.

We have responded to precision machining by creating our own original blades.

Now, more than 60 years later, we use 3D data and the latest simultaneous 5-axis machining centers.

We have inherited and enhanced this know-how to the point of machining parts of all shapes and sizes.

※1 method change

It is also possible to carve from block materials.

Although processing costs are higher, they can significantly shorten production lead times and reduce the cost of production,

This leads to a reduction in risk due to material defects such as nests,

Total benefits can be significant.

We have a lot of processing experience, so please feel free to contact us.